4 strategic sourcing use cases to strengthen your supply chain

IBM Services

FEBRUARY 13, 2024

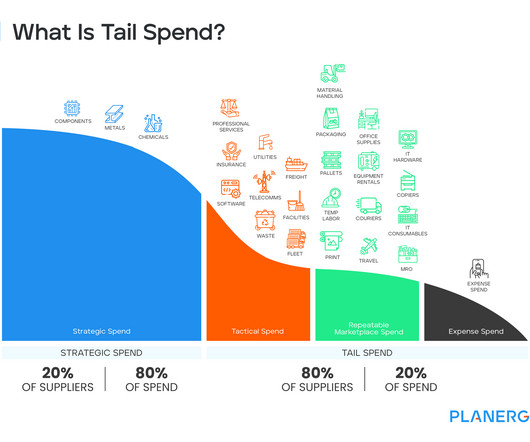

For sourcing teams, that means pivoting their mindset around selecting suppliers from a tactical, lowest-cost-above-all approach to a strategic one. Where tactical sourcing is a short-term strategy, strategic sourcing is for long-term business goals. And from that group, 71% would pay a premium for it.

Let's personalize your content