What is an order type? How does this impact manufacturing in the cloud? Manufacturing by its definition is a process of taking raw materials and turning them into sellable goods. The details of that process in many industries are more complex than the definition. So how do you allow for simplicity and also for the complexity of intricate manufacturing systems? Oracle has come up with a unique solution in their cloud application solution for this.

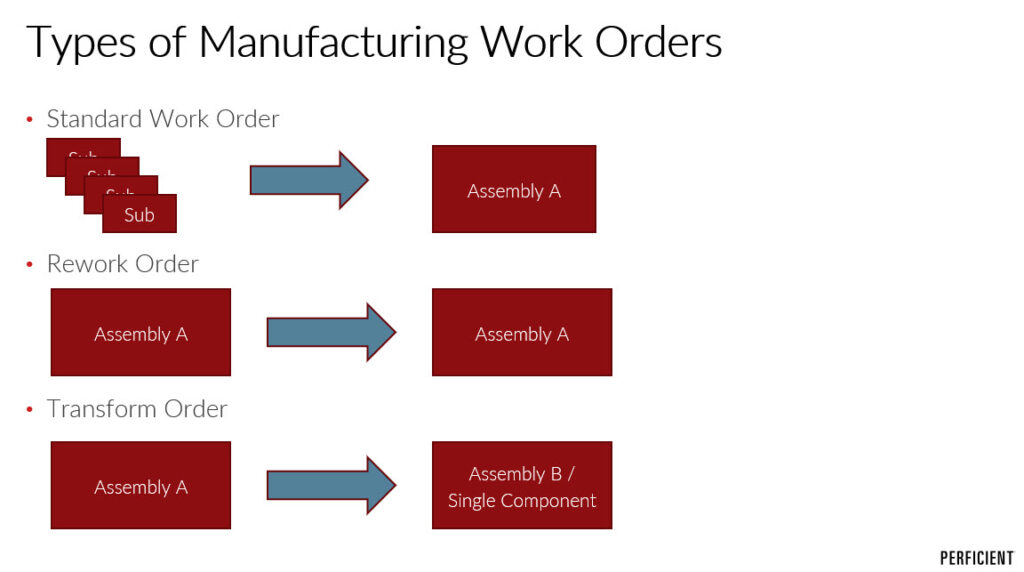

Order Type

Oracle has designed three Order types to handle the manufacturing process. Standard Orders, Rework Orders, and Transformational Orders. Each one of these order types fulfills a specific purpose. We will walk through each one in detail below so that you can better understand how to effectively use them in your cloud solution.

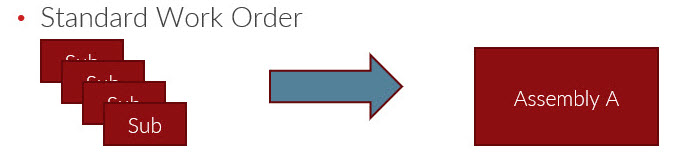

Standard Work Order

Standard Work Orders are the basic work order type. The process is to consume raw materials (Subcomponents) and create finished goods or assemblies. Revenue is generated from the sale of these finished goods. Work orders leverage templates to drive efficiency. These templates include the standard operations, work centers, and item structures. This is what you think of as a standard discrete manufacturing process.

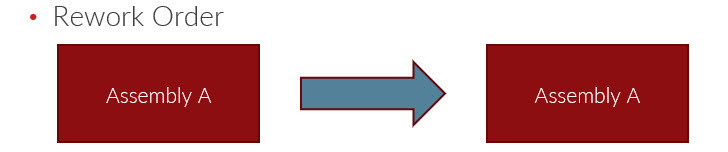

Rework Order Type

Rework Orders take an existing finished good and perform additional work that results in the same finished good. You use rework orders to mend or fix a problem with the product. The additional materials and labor need to be tracked and captured for tracking and costing purposes. If capturing the usage of additional time and materials on a good is key to your operations, then this order type is optimal. An example of this is applying patches to your computer.

The item structure and routings are not defined until after the Order is created. The rationale behind this is that every event is unique. If a repair event is a common occurrence, the repair structure is then standardized. However, I would question why it’s a standard repair and why steps are not being made to eliminate the point of failure.

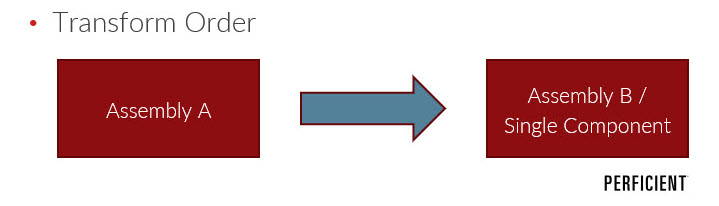

Transform Work Order

Transform Work Orders are where you take one Finished Good (Assembly) and turn it into a different cataloged good or assembly. An example of this would be changing the configuration of a car. The car can drive in North America. Now it must drive in the United Kingdom.

You can also use this order type for breaking down an assembly for a single component. For example, your cellular phone is no longer usable. You must acquire a new phone. Your old phone will be recycled. However, you can save the SD card. You now have an SD card instead of the phone. Another example would be scrapping a laptop but keeping the power cord. Originally, the cell phone or the laptop was what you were tracking. Now, it’s the memory card or power supply.

Utilizing your Order Type

The first step is to properly understand what operation you are doing. Are you creating a new item from many? Changing an item or repairing one? This will put you onto the path for which Order Type you need to utilize. From there, you will then need to configure your structures and routings. Once done, you can execute your work order and have the new inventory to track and sell.

Second, please be aware of which type of manufacturing you are using. Rework and Transform Work Order Types are only available for Discrete Manufacturing in the Oracle Manufacturing Cloud. This means that these order types are not available for Project or Process Manufacturing in the cloud. If you need assistance understanding what type of manufacturing you are using, please see my post on Manufacturing Types. Please also note that work orderless transactions are not available for Rework or Transform Work Orders.

Third, pay attention to how you are planning your manufacturing and production loads. Oracle Cloud planning does not always capture and plan for rework and transformation orders in its supply plan. This will lead to an excess supply if not properly tracked and managed. So, make sure you are aware of this and adjust your planning and reporting tools accordingly.

Conclusion

Whether you are creating, transforming, or reworking an item, the Oracle Manufacturing Cloud now has more options for you to track and trace work order processes. These choices offer more flexibility to easily track and trace your work. Use them wisely and reap the benefits.