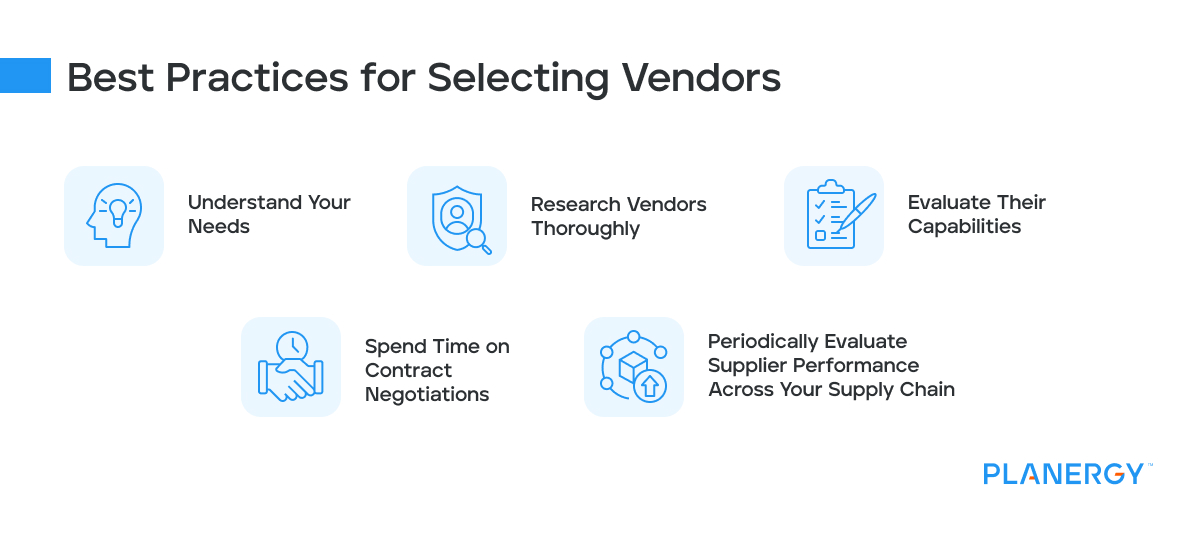

Your procurement team will determine which method to source goods and services based on what you need, when you need it, your budget, and other factors. When signing on a new supply customer, you must consider more than just a good-sounding product and price.

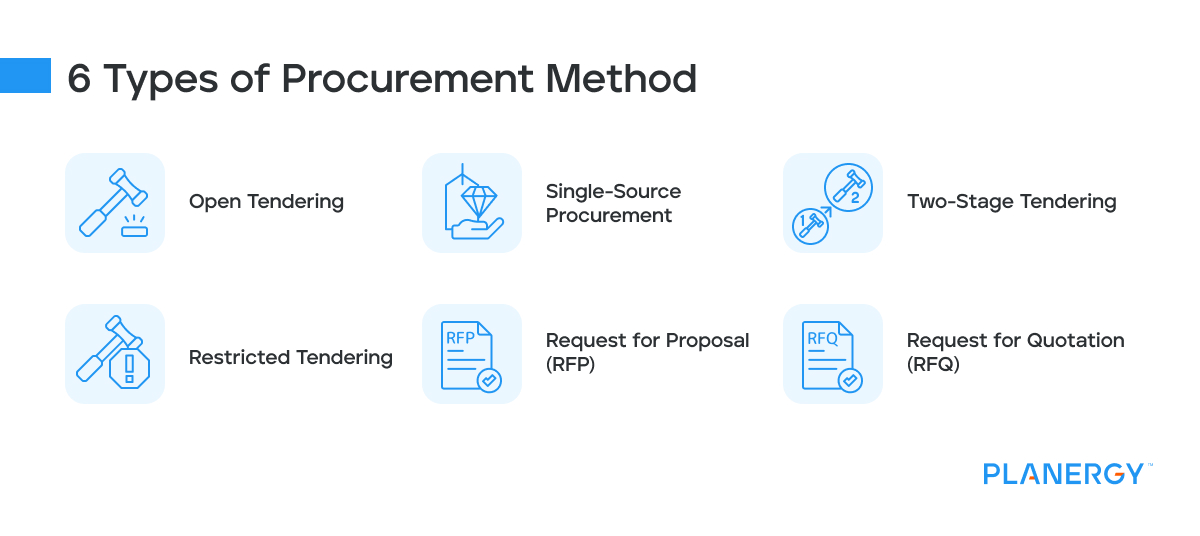

Open Tendering

Open tendering is a procurement method that allows companies to bid on goods in an open competition or solicitation. Open tendering requires a company to advertise locally and have unbiased and coherent technical specifications for the goods sought.

It also requires objective evaluation measures to ensure accurate bids. Open tendering encourages effective competition to obtain goods, emphasizing value for money.

Open tendering is preferable as it allows companies to apply for multiple contracts at once, resulting in more efficient use of resources and reduced cost-over-runs from multiple procurement processes.

Allowing companies to compete with bids can create better value for the organization, so open tendering is generally considered the best procurement method.

Single Source

Single-source procurement, sometimes called sole-source procurement, is the non-competitive procurement method of acquiring goods and services from a single vendor.

This method is used in highly specific circumstances, such as when there is:

- Only one vendor is qualified to fulfill company needs.

- A continuation of previous work

- A clear advantage of using this method over other competitive methods

Non-competitive procurement may also be used when supplies or services are only available from one responsible source, and no other supplies or services will satisfy its requirements.

Single-source procurement can save time and money while ensuring accountability and quality of service. It allows you to ensure you get exactly what you need, when you need it, at a price you can afford.

However, you must use care and consistency to ensure that single-source procurement improves organizational efficiency and outcomes.

Two-Stage Tendering

Two-stage tendering is a procurement method where the buyer invites tender in two stages. The first stage involves bidders submitting their proposals without prices, while the second stage includes price specifications from the selected bidders.

It’s commonly used in construction procurement projects to help streamline the bidding process.

At the prequalification stage, potential vendors are assessed on their financial stability, previous experience, and capacity to carry out the work. Suppliers who pass this initial stage may be invited to submit a detailed technical bid at the second stage.

This will include cost breakdowns and further details on how they plan to deliver the project within budget and time constraints.

In both stages of two-stage tendering, all bids are evaluated against certain criteria set by either public or private bodies before contract award decisions are made.

Restricted Tendering

Restricted tendering, sometimes also called selective tendering, is a competitive procurement method that limits the number of requests for tenders sent out to suppliers or service providers. It ensures that the best-suited and most qualified entities are chosen to acquire supplies or services.

Restricted tendering is commonly used with limited resources and when the procurement process must be streamlined. Shortlisting only the best-suited entities for procurement can save time and money.

By limiting the vendor pool, restricted tendering allows for better selection and reduces the possibility of waste or overpaying.

This selective process helps ensure effective and successful acquisition while saving time and money in the procurement process.

RFPs

RFPs, or request for proposals, are a standard document in the sourcing process. Commonly used to solicit bids from potential vendors. An RFP outlines your requirements, expectations, and all other necessary information so potential suppliers can submit a proposal.

An effective RFP typically includes a detailed description of the project’s purpose, timeline, budget constraints; key deliverables; selection criteria; expectations on how vendors should submit their proposals; and contact information for questions or clarifications.

In addition, if there is expected follow-up service involved, it is important to include details about ongoing support requirements you may have.

By issuing RFPs, you can quickly receive competitive bids to ensure you receive the best goods and services at the most affordable price while meeting your specific requirements.

You should use RFPs when many potential solutions are available but find none fitting perfectly with your needs.

RFQs

RFQs, or request for quotations, are similar to RFPs in that you can use them to get bids from potential vendors. A key difference is that the RFQ should include a pricing quotation.

You generally issue a document to potential suppliers with detailed instructions and specifications. Suppliers then submit their best offer.

These offers typically include pricing information, lead time, and other factors based on your specific needs. You can compare the responses to determine which is best for your company.

You should use an RFQ when you know exactly what you want and need to compare pricing better. Because of this, RFQs are most commonly used when purchasing standard products or raw materials that don’t need customization.